Product Information

| Brand Name | yh | Certification | Model | ||

| Min.Order | 1 Other(s) | Size | CM* CM* CM | Payment Terms | |

| Weight | Customized service | Place Of Origin | Wuhan |

Product Description

Product Description

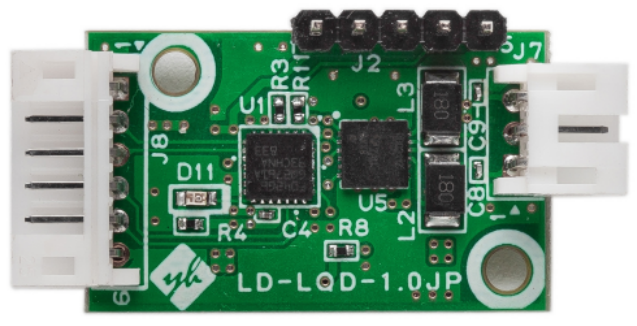

LD-LQD-2.0JP is a miniature capacitive sensor detector, cost-effective, easy to install. Can flexibly switch to liquid level detection and liquid level detection two working modes. Can detect the capacitance change less than 1 pf, can use the matching debugging tool to adjust the sensitivity of the sensor according to the current working conditions, so as to obtain the best detection accuracy. the main limiting factor for the sensitivity of capacitive sensing applications lies in the noise sensitivity of the sensor. Sampling innovative anti- emi architecture, even in high noise environment can maintain the same performance sensor.

Product characteristics

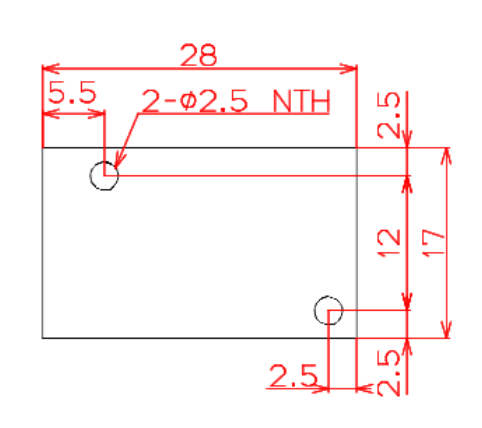

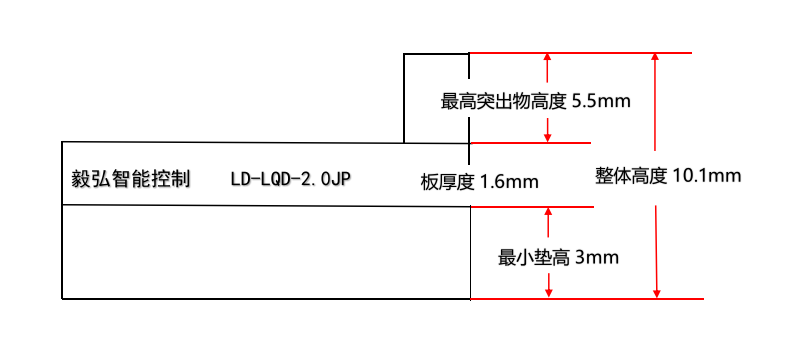

1. Micro volume: 17mm × 38mm × 9mm (with connector 2.5mm 6pin, 2.5mm 3pin).

2. The sensitivity can be adjusted through the matching debugging tools.

3. The minimum capacitance detection is less than 1pf, which is suitable for micro capacitance change.

4. Minimum detection liquid volume: 500ul.

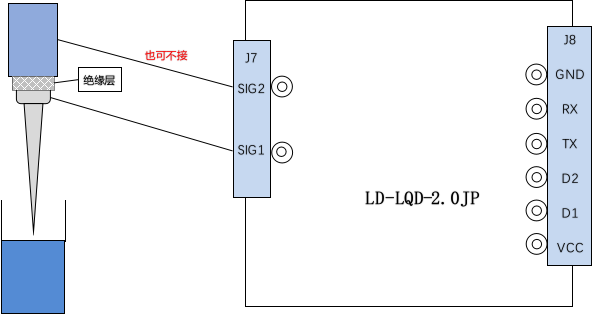

Connection port

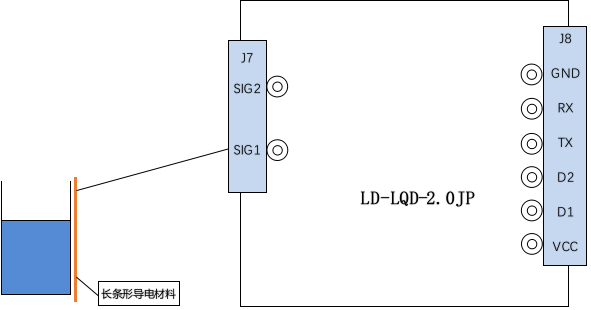

Wiring diagram

Liquid level detection mode

When the product is applied to probe liquid level detection, the SIG1 end can be connected to the inside of the probe, and the SIG2 end can be connected to the outer tube of the probe (or not).

Level Detection Mode

When the product is used to monitor the liquid level of the container, the SIG1 end can be connected to the long strip conductive material, such as aluminum foil. The conductive material is then attached to the outside of the container under test. If the container under test is a movable object, make sure to stick to the outer wall of the container during detection.

Attention to assembly settings:

1、The metal detection film for 1. liquid level detection should be kept at least 10 mm away from the ambient background metal object (recommended distance ≧20 mm), and the metal detection film and the background metal object should be separated and fixed by non-conductive material.

2、the wire connection between the liquid level detection plate and the detection metal detection film, a finer wire should be used to reduce its capacitance relative to the metal body in the back environment, and the line should be as far away as possible from the metal body or the high electromagnetic radiation area. The line should be kept short.

Application area

Suitable for all kinds of automatic medical instruments and equipment.

Mechanical mounting dimensions